- HOME

- Environment(E)

- Realization of a Sustainable and Environmentally Friendly Society

- Recycling-Oriented Society

For Realization of a Recycling Oriented Society

Policies and Basic Approach

The TAISEI Group has established the Group's long-term environmental target "TAISEI Green Target 2050" to "Realization of a Sustainable and Environmentally Friendly Society" as stated in the Environmental Policy, which defines our responsibilities, contributions through our business and initiatives toward the realization of a recycling-oriented society. The "Fundamental Concept" is described in the Environmental Policy.

Responsibilities

As construction is the core business of the Taisei Group, the Group has a keen awareness of the effect of its business activities on the transition to a recycling-oriented society and the impact of the transition to a recycling-oriented society on business activities. We consider it to be our responsibility to increase the green procurement rate and reduce the final disposal rate of construction byproducts, in order to achieve a circular economy.

Contribution Through Our Business

The TAISEI Group identifies the risks and opportunities in anticipation of the achievement of a recycling-oriented society. We strive to develop and disseminate technologies and services relating to soil and groundwater contamination countermeasures, appropriate management of wastes and final disposal sites and so on, and to promote recycling of industrial byproducts, in order to contribute to a recycling-oriented society.

Risks and Opportunities

Transitioning from a linear economy of mass production, consumption, and disposal to a circular economy that minimizes resource inputs and consumption while making efficient use of stock to create added value is a critical global issue. Companies are expected to adopt sustainable procurement practices across their supply chains, including conserving resources, using renewable materials, and addressing plastic pollution in the natural environment.

If the transition to a recycling-oriented society stalls, our group may face risks such as rising material costs due to resource shortages and increased waste disposal costs. Additionally, inadequate efforts by our group may lead to lower evaluations from stakeholders and reduced business opportunities.

Conversely, moving toward a recycling-oriented society opens up opportunities for our group as expanded use of recycled resources that contribute to the realization of a circular economy and increased contracts in environmental restoration projects (e.g., for soil purification). Promoting development and implementation of resource-efficient designs, systems, products, and technologies that consider circular use in construction materials and resources, as we are now doing, strengthens our competitive edge.

We believe that transitioning to a recycling-oriented society presents opportunities for enhancing corporate value and improving evaluations from stakeholders.

Information Disclosure of Integrated Environmental Management(TCFD/TNFD)

Policy / Commitment

- Action Guidelines for Taisei Personnel: Promoting environmental conservation and creation

- Environmental Policy

- TAISEI Green Target 2050: Realization of a recycling oriented society

- Promise of Eco-First

- Taisei Group Sustainable Procurement Guidelines

- Taisei Group Green Procurement Guideline

- Green Procurement Standard Guideline

- Construction byproduct processing manual

- [TAISEI VISION 2030] Achievement Plan

Policy on Business Foundation Development: Sustainability Strategy (Environment and Energy)

Goals

TAISEI Green Target 2050: Group's long-term environmental targets

CE: Achieving and deepening circular economy

- Green procurement* rate: 100%

- Final disposal rate of construction by-products: 0%

*Green procurement:

Taisei Corporation is promoting green procurement, including utilization of recycled materials and selection of materials that take into consideration recycle use. FY2050 target for green procurement rate is 100%.

2030 Environmental Target

- Promotion of green procurement

- Reduction final disposal rate of construction waste: 3.0% or less

Roadmap

KPIs

- As to KPIs, please refer to Materiality.

Initiatives

- United Nations Global Compact “Environment”

- Plastic Smart (Ministry of the Environment)

- Water project (Ministry of the Environment)

- Japan Partnership for Circular Economy: J4CE (Ministry of the Environment, Ministry of Economy, Japan Business Federation)

- Circular Partners(CPs) (Ministry of Economy, Trade and Industry.)

Activities / Efforts

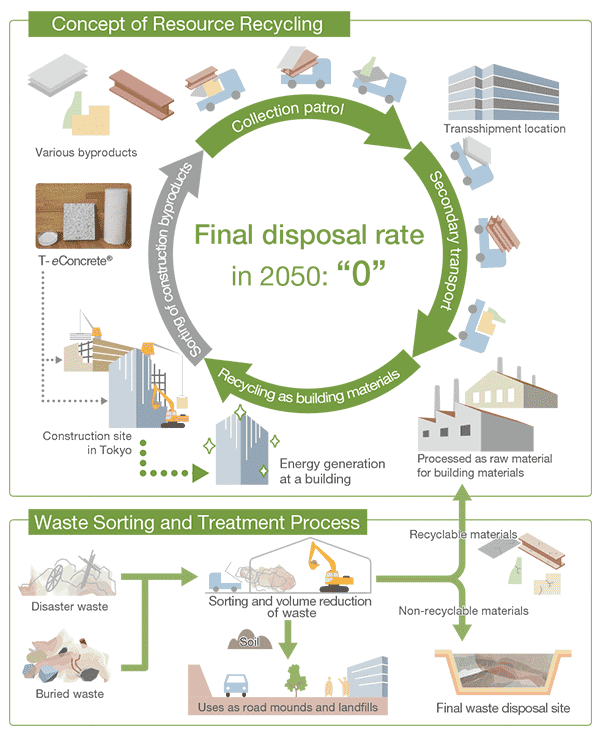

TAISEI Corporation works to add new value to the various by-products generated by its business activities and society, to implement efficient and cyclical use (3R + Renewable) of resources in order to contribute to achieve a circular economy.

Activities for in Effective Resource Utilization

Creation of Added Value of Buildings by Using the Resource Recycling Platform

By calculating/visualizing information on individual construction materials for buildings and resource circularity, value is added to construction itself as a resource.

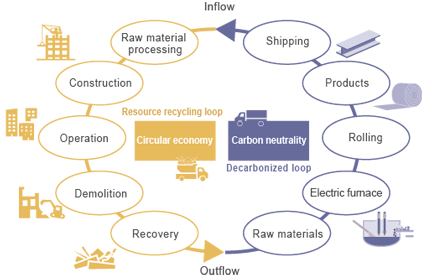

Promotion of Resource Recycling of Steel Materials Through the Introduction of "T-Near Zero Steel"

With the aim of promoting the construction of Zero Carbon Buildings that can realize net zero CO2 emissions in the life cycle of buildings, Taisei Corporation will utilize T-Near Zero Steel, steel materials made from iron scrap, in collaboration with TOKYO STEEL MANUFACTURING CO., LTD. We will contribute to the reduction of newly introduced natural resources through the promotion of resource recycling of steel materials. We will also contribute to the reduction of CO2 emissions by using green electricity for the electricity to be used in the steel manufacturing process.

Promotion of the formation of a resource recycling loop for building materials

We are promoting the formation of a resource recycling loop for glass/aluminum from demolition or new construction site, etc. alignment with manufacturers.

Utilization of recycled plastic

We are promoting the utilization of recyclable plastic for temporary materials, such as safety cones alignment with manufacturers/sellers.

(Recycle use will be doubled by 2030 in the national plastic material recycling strategy).

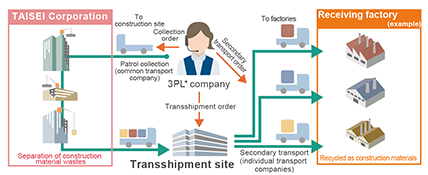

Patrol collection system to promote use of the National Permit System

The construction material scraps that are emitted from construction sites are usually separated at intermediate processing sites. However, even scraps that have been separated are difficult to recycle, and so most of them end up in landfills.

Accordingly, the most effective way for recycling such construction material scraps is to use the National Permit System* that enables construction scraps to be recycled as construction materials or the like at manufacturer factories.

TAISEI uses this system. Moreover, in order to increase the efficiency of transport during use of the system, TAISEI has deployed a Construction By-products Patrol Collection System that unifies the rules of scrap transportation amoung construction material among manufacturers were standardized and makes the same vehicle to patrol multiple sites. At workplaces in the Tokyo metropolitan area, the system collects valuable resources and multi-item construction material wastes including plastic waste and helps to recycle construction material resources.

TAISEI is working to introduce this system to more construction sites, and contribute to promote a circular economy in the construction industry.

- *National Permit System:

A system that with the permission of ministry of the Environment Manufacturers of building materials conduct wide-area collection of their own manufactured product wastes (scraps from product manufacture, etc.) and appropriately process them or recycle them as raw material for products.

Improving the efficiency of resource circulation and transport through the circulating collection patrol system

- *3PL (third-party logistics): Planning and proposing the most efficient logistics strategies and constructing logistics systems on behalf of the consignor company, and comprehensively managing and executing such tasks.

Promotion of Effective Use of Generated Soil by Construction

We are promoting the effective use of generated soil by construction by matching loading and unloading sites through a generated soil management system.

Local Contoribution in Agricultural Field

We have developed improvement / revitalization technology for farmland through bio and greening technologies, and promoted resource recycling initiatives by cooperating with local communities to contribute to resolving local issues.

T-eConcrete® That Utilizes Industrial Byproducts

T-eConcrete® is environmentally friendly concrete that utilizes industrial by-products, such as blast furnace slag (a by-product of steelmaking) and fly ash (a by-product of coal-fired power plants) as cement substitutes. It is used as a construction material for tunnel segments and natural stone-like building materials (stone-like building materials used as secondary products of T-razzo zero cement type). We are promoting utilization of T-eConcrete®/ Carbon-Recycle with using calcium carbonate that is produced from capturing CO2.

-

Segment of shield tunnel

(T-eConcrete®) -

T-razzo zero cement type

(Application examples)

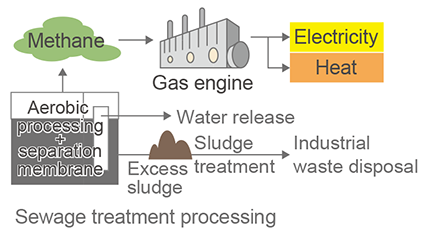

Producing energy from sewage treatment processes

TAISEI is working to develop and demonstrate new sewage treatment processes that generate methane from the organic matter contained in the sewage that is emitted from our daily life.

Activities to Reduce Environmental Impact from Waste

Recycled Use of Waste Plastics

- Construction materials, packaging materials, and other waste plastics are sorted thoroughly and properly recycled by specialized disposal companies. In addition, we are implementing measures to utilize waste plastic by combining it with waste wood products and creating artificial recycled wood products.

- Taisei Corporation supports the Plastics Smart Campaign by the Ministry of the Environment.

*Plastics Smart

A campaign by the Ministry of the Environment to promote “a smart way of dealing with plastic” nationwide, including thorough elimination of littering and illegal dumping, and thorough reduction of single-use plastic and sorting and collection.

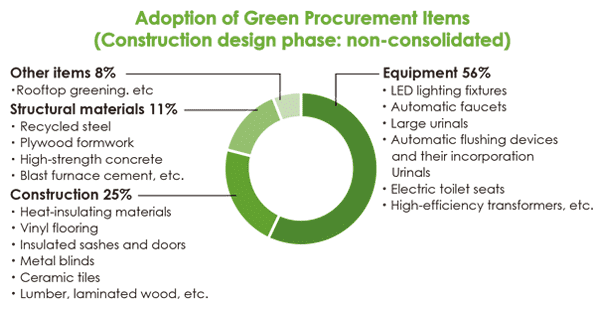

Cooperation with suppliers based on Green Procurement Guidelines

In 2001, TAISEI Corporation formulated Green Procurement Guidelines with the aim of selecting and promoting the use of construction materials and methods with low environmental impact in the design, construction, operation and demolition stages of structures. The Guideline refers and reflects the content of the Act on Promoting Green Procurement (Act on Promotion of Procurement of Eco-Friendly Goods and Services by the State and Other Entities) and the target items are reviewed each year and new items are added. In FY2023, 109 items are listed in the guideline.

In addition, TAISEI implement target management for the number of adopted green purchasing items during construction and design stages; an average of 13.7 items were purchased in FY2023. Use of the Guideline on a company-wide basis will lead to cyclical use of resources as well as energy conservation, reduction of CO2 emissions, resource conservation, elimination of the use of hazardous substances and conservation of the natural environment.

Green Procurement Guidelines(excerpt)

A set of guidelines on what the Company and its suppliers should do together. They can be summarized about selection of Green Procurement as

- Low life-cycle CO2: (LCCO2): Lifetime CO2 emissions during the entire period of use, from construction to disposal

- Energy and resource conservation

- Low amount of construction waste generated during construction and demolition

- Consideration of the use of recycled materials and recycling

- Freedom from harmful substances

- Consideration of biodiversity and local environment

*LCCO2 : Lifetime CO2 emissions during the entire period of use, from construction to disposal

In addition, We have Green Purchasing Standard Guidelines. Guidelines that define important aspects of reducing the environmental impact when purchasing office supplies, equipment, office automation (OA) equipment, etc., or receiving services for use in offices.

Waste Separation and Volume Reduction Technologies

Separation of buried wastes

By separating wastes and reducing waste volume, TAISEI reduces the environmental burden of the wastes generated by illegal dumping and natural disasters (buried wastes and disaster wastes) so they can be appropriately dealt with as usable recycle resources and so on. Viscous soil that is sticky and has a high water content is mixed with T-Quick Dry, a separation support material, and then screened with a sieve. This increases separation efficiency and restores the healthy soil environment.

Moreover, the disaster wastes of at the Great East Japan Earthquake of 2011 were also separated and volume-reduced, to contribute to reduce environmental burdens.

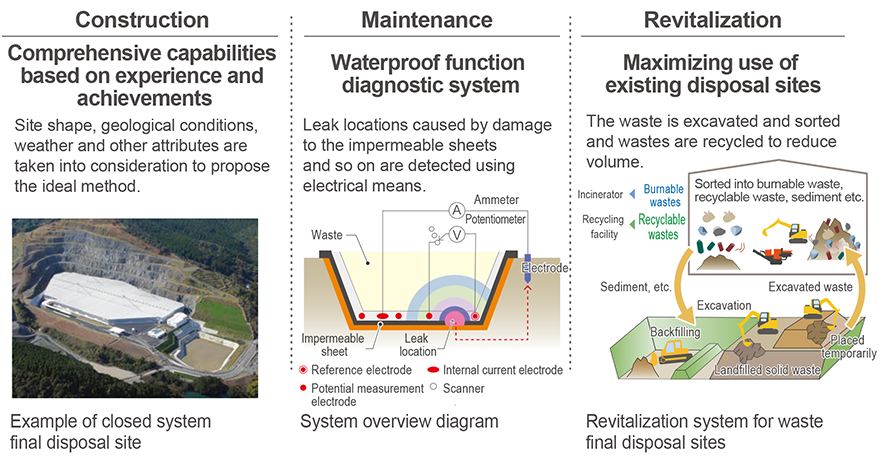

Final Disposal Site Technologies for Next Generation

Building, maintaining and restorating final disposal sites

TAISEI Corporation's technologies for final waste disposal sites are environmentally conscious technologies that take into account not only site creation but also site maintenance and restoration to improve the on site environment.

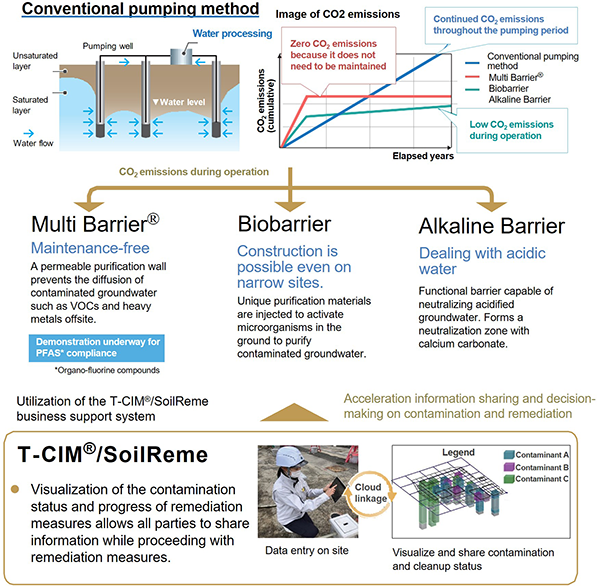

Soil and groundwater remediation technology with low CO2 emissions

This in-situ barrier technology, which emits less CO2 than conventional pumping methods, prevents the spread of contamination and regenerates the groundwater environment.